What is Warehouse Management? A Beginner's Guide to Smarter Inventory Control

To Know about Warehouse Managemnt, It doesn’t matter if you manage a small web store or a huge cross-dock center-learn the basics and you shield profits while keeping shoppers pleased.

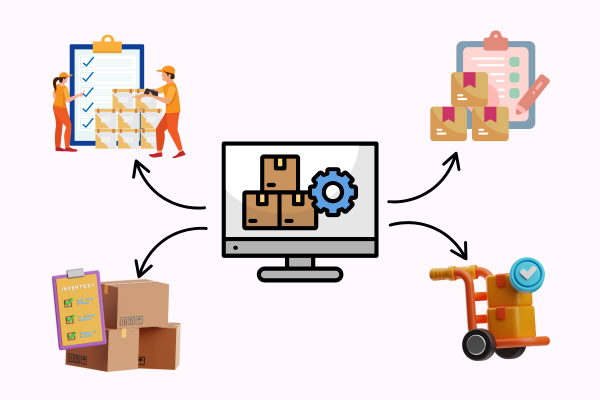

What is Warehouse Operations Management, Plain and Simple

In plain English, warehouse management equals smart planning and logistics which means goods roll in with a home to stand by and roll out on time. From when a delivery truck backs up and drops off a pallet to when a box lands on the front doorstep, each motion requires a planned path and an eye of vigilance.

Management is about making sure the paperwork for incoming deliveries are processed, space is secured for shelving and ease of picking, our stock levels are controlled, picking is correct, and our order is sent without mistakes. This simple list could go on to a book of 100s of actions, so when sales go from flat to growing…a functional operation is not luxury, but a necessity.

Key Components of Effective Warehouse Management

Inventory Tracking and Control

Accurate, transparent records prevent hidden shortages and unexplained pools of surplus stock. Nowadays, many companies depend on real-time inventory tracking to check levels every minute, identify slow movers, and issue reorder signals without second-guessing.

Strategic Layout and Organization

How you arrange a warehouse shapes everything that follows. Place fast-moving goods within arm’s reach, and the long walks and lost minutes vanish. Staff grab orders quicker, and each shipment hits the truck on schedule.

When your marketing team comes up with a hot lead at 2 PM, your sales team knows about it at 2:01 PM. When a deal closes, the entire organization can celebrate knowing everyone is included still.

Order Processing and Fulfillment

A smooth workflow at the packing table lets customers open boxes the moment they expect to. Clear paths, zip ties instead of tape, and tight links with carriers make that possible.

Technology's Place in Contemporary Warehouse Management

Warehouse Management Systems (WMS)

You can picture a WMS as the facilities nervous system, operating out of sight yet commanding nearly every task. It absorbs routine busywork, slashes errors, and keeps every worker, robot, and conveyor belt aligned with one common goal.

With features such as automated counts, guided picking paths, and live dashboards, the system turns raw data into instant shortcuts. Because it talks to accounting, sales, and transport software, information flows without stop-and-go.

Barcode and RFID Technology

Barcodes and [RFID tags] have changed the scanning game for good. Scanners or antennas read items in a blink, chopping human error and feeding managers clear numbers.

When these readers swarm the shelves, workers find products in seconds, counts adjust without pencil and slip, and stock levels stay accurate.

Advantages of Professional Warehouse Management

Enhanced Customer Satisfaction

The impact of efficient warehouse operations is instantly revealed when the customer opens the door to their order. Orders that leave the floor quickly while arriving at the buyers home on time and intact lead to repeat business and referrals.

Reduction in Cost and Efficiency Increase

A good warehouse will have a positive impact on overhead by reducing the amount of time items are stored in the warehouse, reducing the number of errors, and reducing shipping costs. An efficient pick and accurate sort process not only saves money; more importantly, it saves labor hours and costs; allowing businesses to invest in growth.

Proper management eliminates wasted money.

By implementing a better pick process, they save on hourly wages; by keeping the only stock available that is actually needed, they reduce carrying costs; smarter packing eliminates dead weight, and using the right carrier reduces shipping spend.

Enhanced Inventory Accuracy

Clear, real-time counts stop the headaches of selling out-of-stock items or turning away shoppers because phantom shelves appear empty. Solid data also sharpens forecasts and guides smarter buying.

Better Space Utilization

Thoughtful layout and storage tricks squeeze more out of every aisle, meaning you might put off that pricey new building for years. In fact, simple stacking and slotting tweaks can boost capacity by twenty to thirty percent without adding a single square foot.

Common Warehouse Management Challenges

Yet plenty of sites still lean on clipboards and hand-writing labels, a habit that invites mistakes and drags the clock. Paper trails delay answers, make tracking lost items harder, and rob managers of the swift data they need to steer daily choices.

When sales patterns swing with the seasons, warehouses need plans that bend instead of breaking. Busy stretches can flood an ill-prepared site, while quiet weeks let expensive space sit empty.

Every aisle and dock door depends on people who know safety rules, software screens, and quality checks. Frequent departures pull focus from work and push up the cost of bringing new hires up to speed.

Getting Started with Warehouse Management Optimization

Assess Your Current Operations

Look closely at how things flow today. Where do moves stall, what numbers lag, and which tasks feel clumsy? Recording these gaps gives you a target for fixes. Implement Gradual Improvements

Instead of ripping out the whole system, treat change like building blocks. Tackle small, clear wins first, then plan bigger upgrades once the team feels the benefit.

Invest in Staff Training

No program or gadget will shine unless trained users bring it to life. Regular, hands-on lessons let staff use every feature and adapt smoothly when tweaks arrive.

Transform Your Warehouse Operations Today

Effective warehouse management transforms chaotic operations into streamlined, profitable systems. The investment in proper management practices pays dividends through improved efficiency, reduced costs, and enhanced customer satisfaction.

Ready to revolutionize your warehouse operations? Businessezee offers comprehensive warehouse management solutions tailored to businesses of all sizes. Our expert consultants will assess your current operations, identify improvement opportunities, and implement systems that drive measurable results.

Contact Businessezee today for a free warehouse management consultation and discover how we can optimize your inventory control processes for maximum profitability.